公司產品

公司簡介

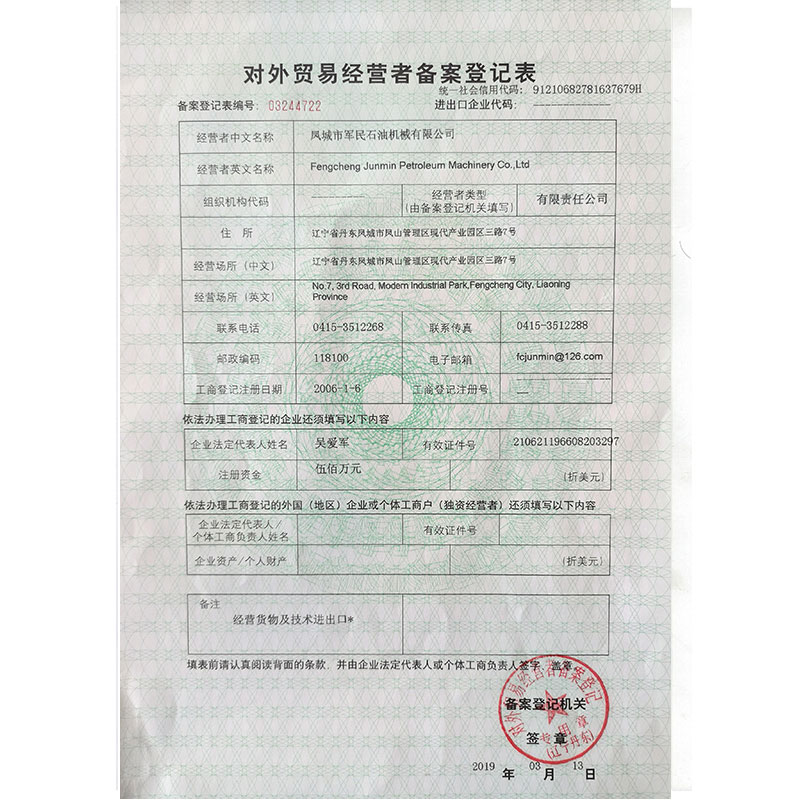

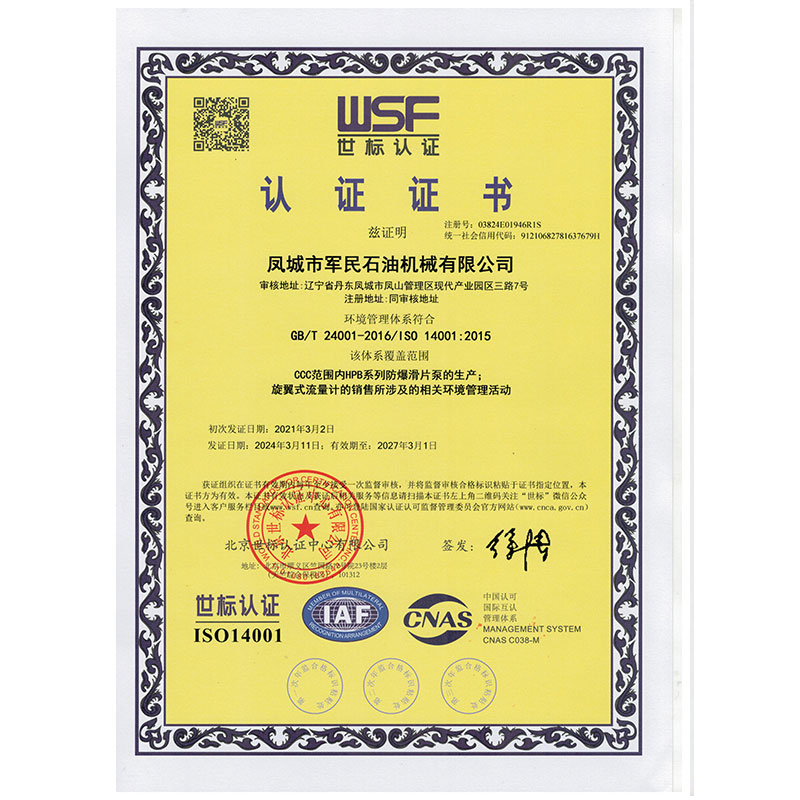

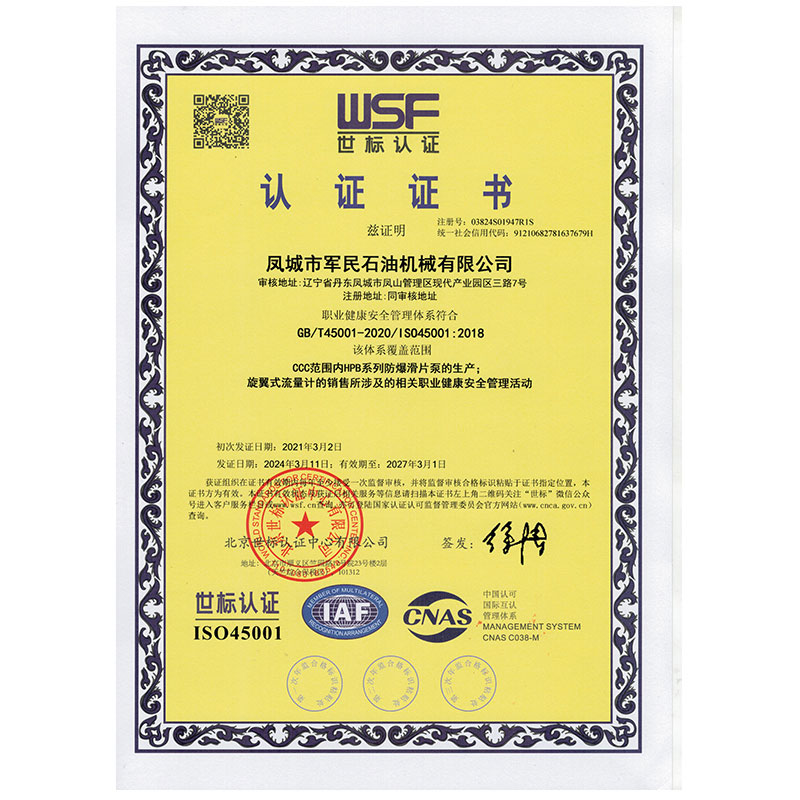

鳳城市蜜桃视频APP色版网站石油機械有限公司位於遼東明珠美麗的鳳凰山腳下鳳城市現代產業園區,距中國邊境城市丹東50公裏,距鳳城市高速出口僅1.5公裏,沈丹高速,沈丹高鐵,沈丹鐵路,304國道在鳳城交匯,交通便利。我公司是中華工商業聯合會石油業商會會員單位,高新技術企業,重合同守信用企業,AAA級信用企業,分別通過了ISO9001-2015質量管理體係認證,GB/T45001-2020/ISO45001:2018職業健康管理體係認證,GB/T24001-2016/ISO14001:2015環境管理體係認證;

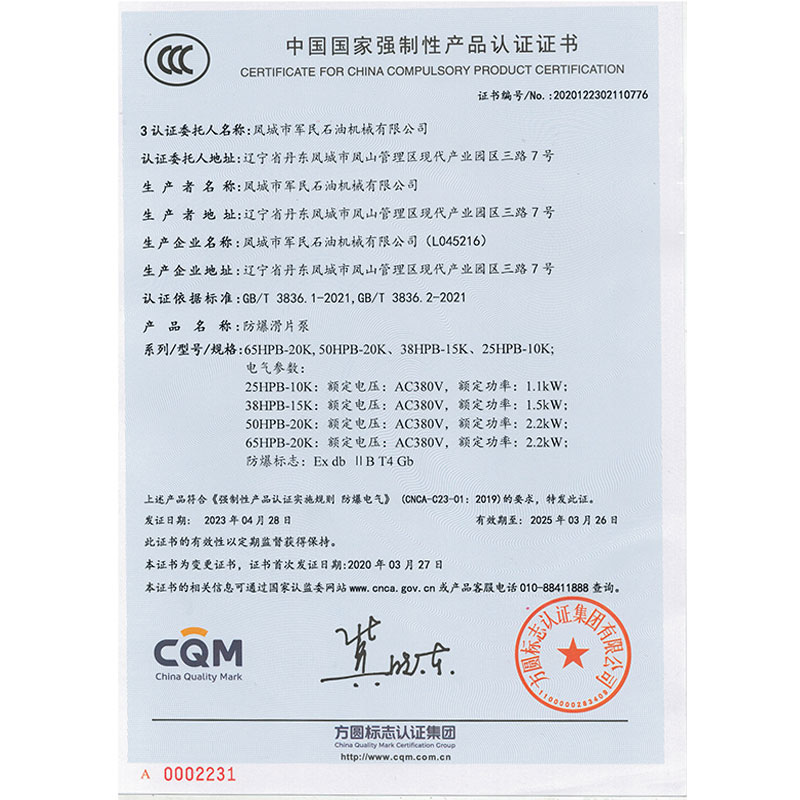

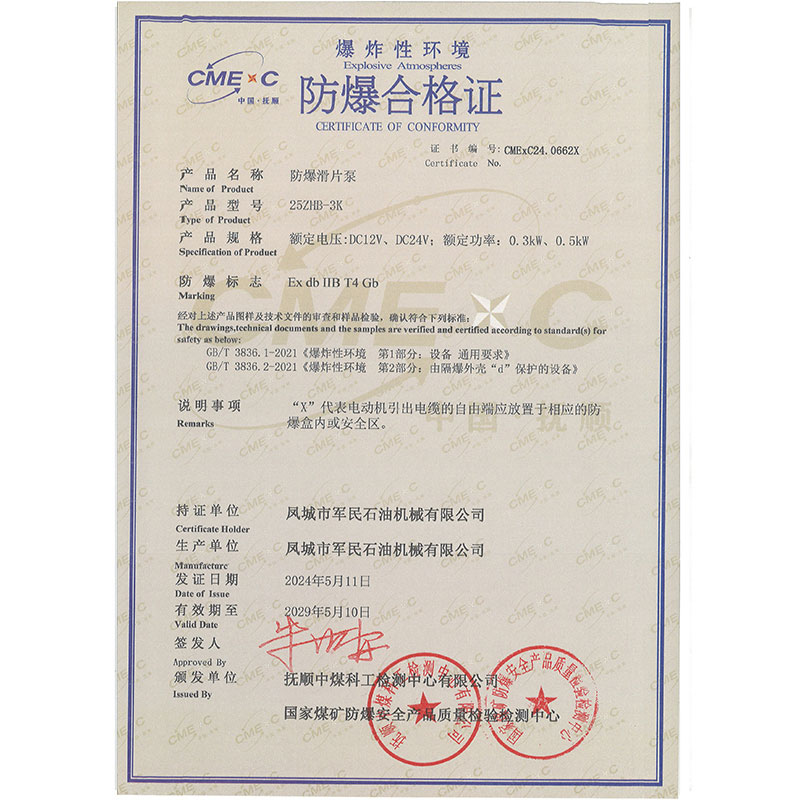

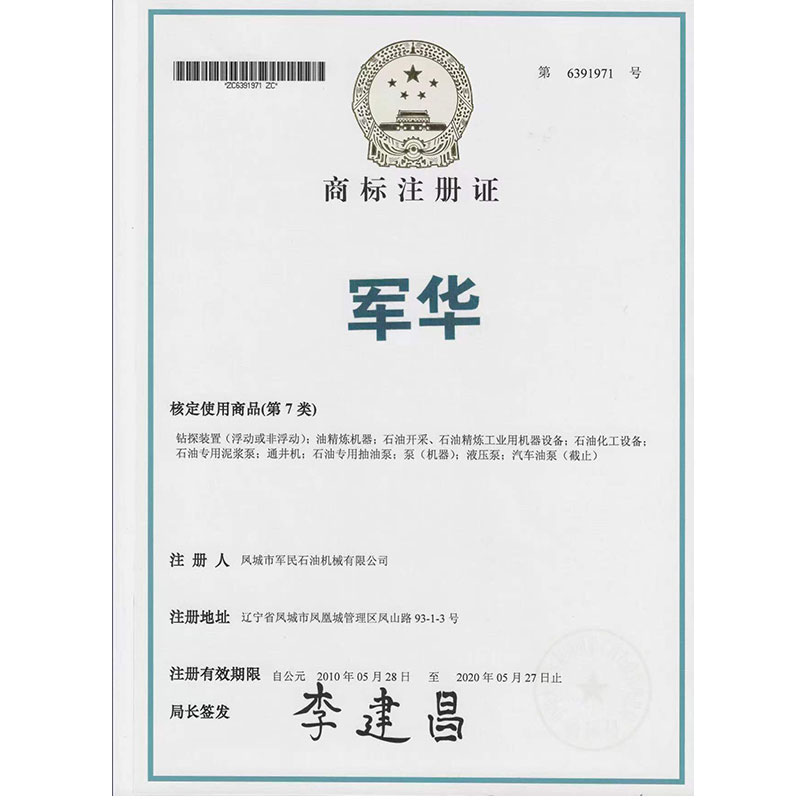

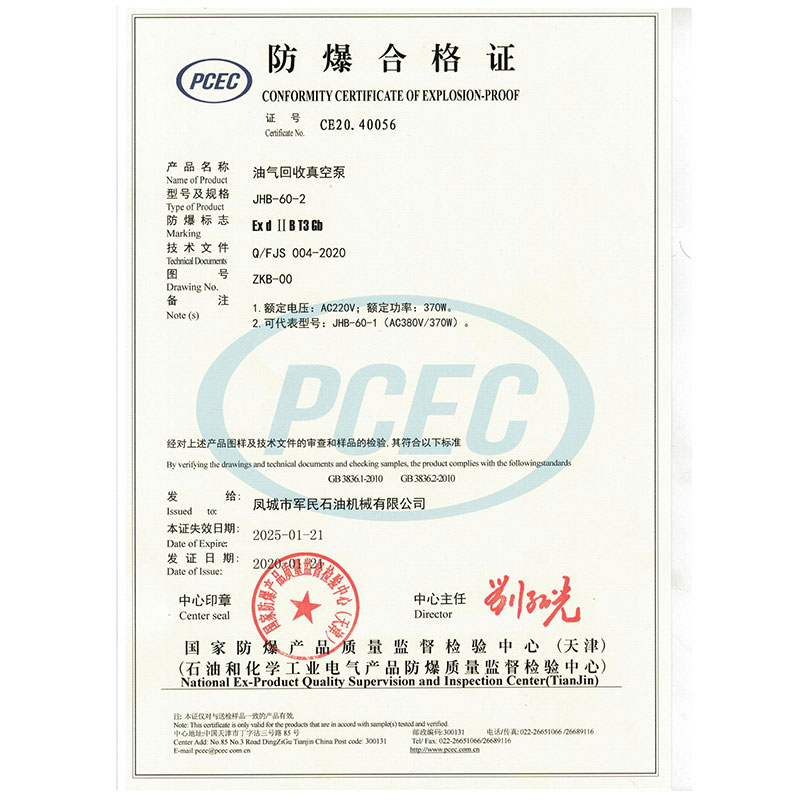

公司擁有先進的設計、製造、試驗和質檢能力,生產條件完善;一貫重視產品質量,並對產品持續改進創新,公司產品獲得實用新型發明專利11項,計算機軟件著作權登記證書2項,尚有正在申請中的專利若幹項,其中HPB係列及ZHB係列防爆滑片无码人妻精品一区二区蜜桃网站已通過防爆電氣產品質量監督檢驗認證和中國強製性產品CCC認證,是國內同行業中很早獲得由“質檢總局”頒發的《工業產品生產許可證》企業,HPB係列防爆滑片泵已被中石油、中石化、中海油以及部隊指定為優先入圍產品。公司始終堅持“以市場為導向,以技術為基礎,以質量求生存,以誠信求發展”的宗旨,竭誠為廣大用戶服務;鳳城市蜜桃视频APP色版网站石油機械有限公司真誠的歡迎業內各界朋友、新老客戶光臨惠顧。

公司實力

0.136807s

中文

中文 English

English Россия

Россия 鳳城蜜桃视频APP色版网站石油機械有限公司

鳳城蜜桃视频APP色版网站石油機械有限公司